Ukukhetha i-twist drill bit efanele yephrojekthi yakho kuhlanganisa ukuqonda izici ezintathu ezibalulekile: impahla, ukunamathela, nezici zejometri. Ngayinye yalezi zici idlala indima ebalulekile ekusebenzeni nasekuqineni kwe-drill bit. Nakhu ukuhlolisisa indlela yokwenza isinqumo unolwazi.

Okubalulekile

1. High-Speed Steel (HSS):

I-High-Speed Steel (HSS) ibilokhu ibalulekile ekusikeni amathuluzi isikhathi esingaphezu kwekhulu, ihlonishwa ngokusetshenziswa kwayo okubanzi nokufinyeleleka kwayo. Ama-drill bits e-HSS aziwa ngokuguquguquka kwawo, asebenza kahle ngakho kokubili ukubhola ngesandla kanye nezinkundla ezinzile njengemishini yokubhoboza. Inzuzo eyinhloko ye-HSS ikhono layo lokulola kabusha, ithuthukisa ukuphila isikhathi eside kwezingcezu zokubhoboza futhi ikwenze kube ukukhetha okungabizi kakhulu kwamathuluzi e-lathe. Ngaphezu kwalokho, i-HSS inamabanga ahlukene, ngalinye linezingoma ezihlukene zokubhekana nezidingo ezithile zokusika. Lokhu kuhlukahluka kwamabanga ensimbi kwengeza ekuzivumelaniseni nezimo kwe-HSS, okuyenza ibe yingxenye eguquguqukayo nebalulekile emisebenzini yemishini eyahlukahlukene.

2. I-Cobalt HSS (HSSE noma i-HSSCO):

Uma kuqhathaniswa ne-HSS yendabuko, i-Cobalt HSS ibonisa ubulukhuni obuphakeme nokubekezelela ukushisa. Lokhu kuthuthukiswa kwezakhiwo kuholela ekuthuthukisweni kokumelana nokuhuzuka, okwenza izingcezu zokubhoboza ze-HSSE ziqine futhi zisebenze kahle. Ukufakwa kwe-cobalt ku-HSSE akugcini nje ngokuba nomthelela ekukhuleni kwayo ukumelana nokuhuzuka kodwa futhi kuthuthukisa impilo yayo yonke. Ngokufana ne-HSS evamile, amabhithi e-HSSE agcina inzuzo yokulolaka kabusha, okunweba nakakhulu ukuphila kwawo okusebenzisekayo. Ukuba khona kwe-cobalt ku-HSSE kwenza lezi zingcezu zifaneleke ikakhulukazi imisebenzi yokumba enzima kakhulu lapho ukuqina nokumelana nokugwazeka kubalulekile.

3. I-Carbide:

I-Carbide iyinhlanganisela ye-matrix yensimbi, eyenziwe ngokuyinhloko nge-tungsten carbide enezibophezelo ezihlukahlukene. Idlula kakhulu i-HSS ngobulukhuni, ukubekezelela ukushisa, kanye nokumelana nemihuzuko. Nakuba ebiza kakhulu, amathuluzi e-carbide ahamba phambili esikhathini sokuphila kanye nesivinini somshini. Zidinga okokusebenza okukhethekile ukuze ziphinde zilole.

Ukugqoka

I-Drill bit coatings iyahlukahluka kakhulu futhi ikhethwa ngokusekelwe kuhlelo lokusebenza. Nakhu ukubuka okufushane kwama-coatings ajwayelekile:

1. Okungagqotshiwe (Kukhanya):

Umbala ojwayeleke kakhulu we-HSS drill bits. Ilungele izinto ezithambile ezifana nama-alloys e-aluminium nensimbi ye-carbon ephansi, amathuluzi angamboziwe yiwo athengekayo kakhulu.

2. I-Black oxide Coating:

Ihlinzeka ngokugcotshwa okungcono nokumelana nokushisa kunamathuluzi angamboziwe, ithuthukisa ubude bempilo ngaphezu kuka-50%.

3. I-Titanium Nitride (TiN) Coating:

Izingcezu zokubhola ezinamekwe nge-Titanium zisebenza kahle ezimeni eziningi zohlelo lokusebenza ngenxa yezici zazo ezihlukile zokusebenza. Okokuqala, Ithuthukisa ukuqina nokumelana nemihuzuko ngokusebenzisa i-coating, ivumela i-bit ukuthi ihlale ibukhali ngenkathi ibhoboza izinto eziqinile, futhi inikeza impilo yesevisi ende. Lezi zingcezu zinciphisa ukungqubuzana nokwakheka kokushisa, zikhuphule ukusebenza kahle kokusika ngenkathi zivikela ibhithi ekushiseni ngokweqile. Izingcezu ezifakwe nge-Titanium zilungele ukusetshenziswa ezintweni eziningi, njengensimbi engagqwali, i-aluminium nokhuni, okuzenza zilungele ubunjiniyela kanye nezinhlelo zokusebenza zasendlini. Ngaphezu kwalokho, lezi zingcezu zingena ezintweni ngokushesha futhi zihlanzeke, zinikeze indawo yokusika ehlanzekile. Nakuba imishini yokubhoboza i-titanium ingase ibize ngaphezu kokuprakthiza okujwayelekile, ukusebenza kahle kwakho okuphezulu nempilo ende kubenza babe nembuyiselo enhle ekutshalweni kwezimali ezinhlelweni ezidinga ukumelana nokuhuzuka okuphezulu kanye nokusikwa okunembile.

4. I-Aluminium Titanium Nitride (AlTiN) Coating:

Okokuqala, izimbotshana ze-AlTiN zimelana nokushisa ngokwedlulele, zizenza ziphumelele ekusikeni ngesivinini esikhulu kanye nomshini wama-alloys asezingeni eliphezulu. Okwesibili, lokhu kunamathela kuthuthukisa kakhulu ukumelana nemihuzuko futhi kwandise ukuphila kwamathuluzi, ikakhulukazi uma kwenziwa izinto eziqinile njengensimbi engagqwali, ama-titanium alloys nama-alloys asekelwe ku-nickel. Ngaphezu kwalokho, ukufakwa kwe-AlTiN kunciphisa ukungqubuzana phakathi kwe-drill bit kanye ne-workpiece, ukuthuthukisa ukusebenza kahle komshini nokusiza ukufeza indawo yokusika ebushelelezi. Futhi inokumelana okuhle kwe-oxidation kanye nokuzinza kwamakhemikhali, okuyenza ikwazi ukugcina ukusebenza ezindaweni zokusebenza ezinzima. Sekukonke, ama-AlTiN-coated drills alungele izinhlelo zokusebenza zemishini enesivinini esikhulu, enembe kakhulu, futhi afaneleka ngokukhethekile ukuphatha izinto eziqinile ezibeka inselele ekuzibhoboleni okuvamile.

Izici zeJomethrikhi

1. Ubude:

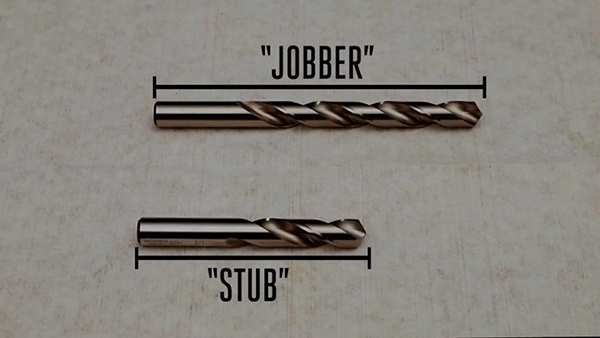

Isilinganiso sobude nobubanzi buthinta ukuqina. Ukukhetha i-drill bit enobude obanele bomtshingo bokukhishwa kwe-chip kanye nokugqwala okuncane kungathuthukisa ukuqina nempilo yamathuluzi. Ubude bomtshingo obanele bungase bulimaze kancane. Kunamazinga ahlukahlukene obude ongawakhetha emakethe. Obunye ubude obujwayelekile iJobber, stubby, DIN 340, DIN 338, njll.

2. I-Engeli Yephoyinti Lokubhola:

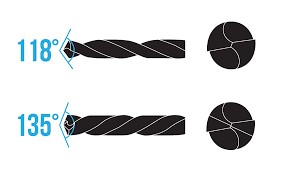

I-engeli yephoyinti engu-118° ivamile ezinsimbi ezithambile njengensimbi ye-carbon ephansi ne-aluminium. Ivamise ukuntula ikhono lokuzicabangela, idinga imbobo yokuhlola. I-engeli yephoyinti engu-135°, nesici sayo sokuzibekela eceleni, isusa isidingo sembobo emaphakathi ehlukile, konga isikhathi esibalulekile.

Sengiphetha, ukukhetha i-twist drill bit efanele kuhilela ukulinganisa izimfuneko zezinto ezimbayo, ubude besikhathi obufiswayo kanye nokusebenza kwebhithi, kanye nezidingo ezithile zephrojekthi yakho. Ukuqonda lezi zici kuzoqinisekisa ukuthi ukhetha i-drill bit esebenza kahle kakhulu nesebenza kahle ngokwezidingo zakho.

Isikhathi sokuthumela: Jan-10-2024